Growing up in India, Surjith Krishna was intrigued by the tall buildings surrounding him.

“I had a passion for civil engineering from an early age,” he said. “I was really fascinated by the tall infrastructure that was in my area. I admired the brains behind those structures.”

Later, Krishna worked as a land surveyor, however, over time, his interests evolved. With a newfound interest in ecology, he moved from looking up at buildings to looking down at water for inspiration.

Globally, two billion people, or 26% of the population, do not have safe drinking water, and there is imminent risk of a global water crisis, according to a 2023 report from UNESCO.

“Water is becoming one of the most scarce commodities,” he said. “Everybody needs water to live. Not having clean water causes deadly human diseases like liver damage and skin irritation. This issue has to be eradicated as soon as possible. So that is my primary goal.”

Eutrophication, a major environmental issue, occurs when excessive nutrients in water lead to harmful consequences, including algae blooms. These blooms can result in ecosystem damage, human health issues and increased water treatment costs.

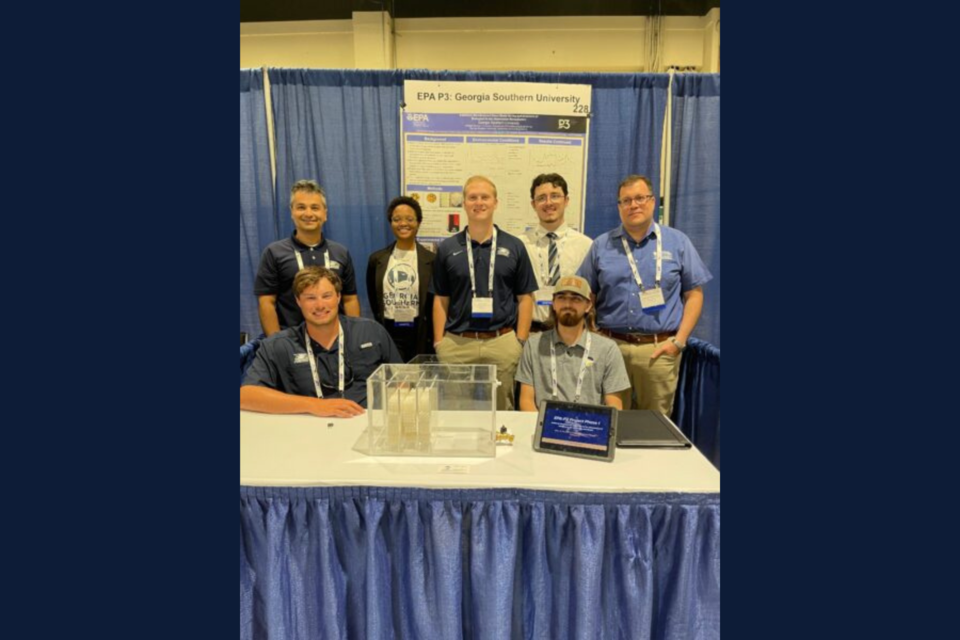

Krishna, a civil engineering student at Georgia Southern University, is part of a team of student researchers funded by a $100,000 grant from the Environmental Protection Agency (EPA) to find practical solutions for cleaning water systems. The team is developing a biofilter for water streams which will use algae and other organic elements to absorb these nutrients.

Krishna’s involvement, as well as that of many other students, is an aspect of the project that Principal Investigators Kamran Kardel, Ph.D., associate professor of manufacturing engineering in the Allen E. Paulson College of Engineering and Computing, and Francisco Cubas Suazo, Ph.D., associate professor of Civil Engineering and Construction, are particularly excited about.

Cubas Suazo, who teaches a watershed management class, said he and Kardel intentionally designed the project to prioritize student participation.

“I see a lot of students interested in trying to solve this problem,” said Cubas Suazo. “It was very important to us to design this project to involve as many students as possible, both undergraduates and graduates, so that they can take part in a real-world solution. We also have a lot of students living in rural areas who can provide different perspectives to help us inform our approach.”

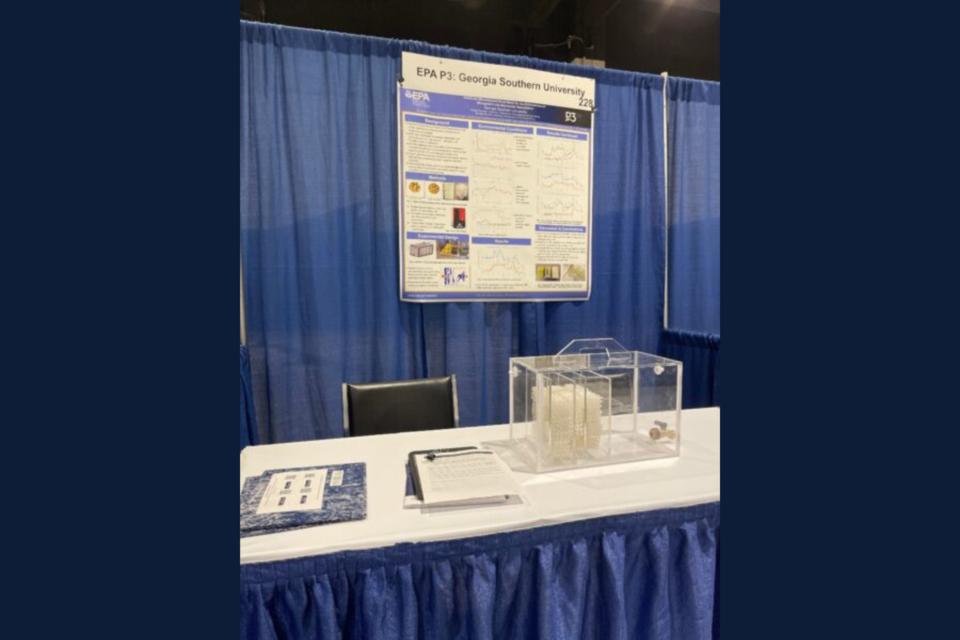

The biofilter is a 3D-printed cube with void spaces to promote biofilm growth, allowing algae to flourish and effectively capture phosphorus and nitrogen as runoff water flows through. Though the exact dimensions of the filter are still being finalized, the project has already garnered significant attention for its potential impact on water quality.

“This biosystem is acting like an agent for us,”said Kardel “They can do the phenomenon for us and improve the quality of the water that targets runoff from the urban and agricultural watersheds.”

The use of 3D printing is also garnering attention. Brennen Smith, a construction engineering major preparing to graduate this December, believes that the mainstreaming of 3D printers is a game changer for this industry and many others.

“You can make whatever shape you want,” he said. “The resources needed are relatively low, the material is pretty cheap and with 3D printers’ axis system, you are able to produce a model to fit any mold. 3D printers have made engineering concepts as a whole easier to produce as models.”

Kardel and Cubas Suazo added that the ease and flexibility of 3D models are especially important in this context because they allow the filter to employ a higher surface area-to-volume ratio. This means more algae can grow in a smaller area, increasing the biofilter’s efficiency and effectiveness.

“The idea of 3D printing in manufacturing is not necessarily new, but in the past, maybe the resources weren’t there to apply it to biofilters,”said Kardel. “We’ve found that this technology is the only way to maximize that high surface area-to-volume ratio critical to a biofilter’s success.”

Furthermore, the professors noted that the ease of use afforded by 3D-printed materials will make maintenance and upkeep much easier, preventing the clogging and decay currently seen in biofilters.

Though still in its early stages, Kardel noted that the project could have broader applications for water treatment in urban and rural settings.